LED OEM Service

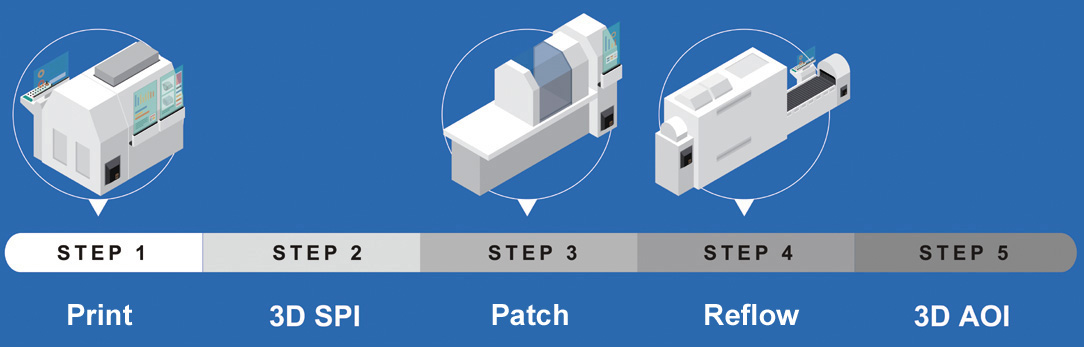

Production process

We provide professional SMT (S.M.T - Surface Mount Technology) process services to meet the needs of Industry 4.0 intelligence, automation and customization, including the printing, assembly, testing and packaging of electronic products with LED light source. Automated production line is capable of customization, fast and mass production. However, due to the miniaturization of parts and the increase in density, the risk of circuit board defects has increased. Thus, the production line is enhanced with AOI optical inspection instruments for multi-level error detection to control risks and improve product yields, providing quality manufacturing services.

Production Capability

Production capability can cover FR4, MCPCB, FPC and rigid-soft composite boards, and various styles of shapes (round, trapezoidal, etc...)

Base plate size: 50x50mm (min.) 1200x370mm (max.)

Component height: 25mm (max.)

Component size: 0201*1~74mm/50x150mm

Base plate size: 50x50mm (min.) 1200x370mm (max.)

Component height: 25mm (max.)

Component size: 0201*1~74mm/50x150mm

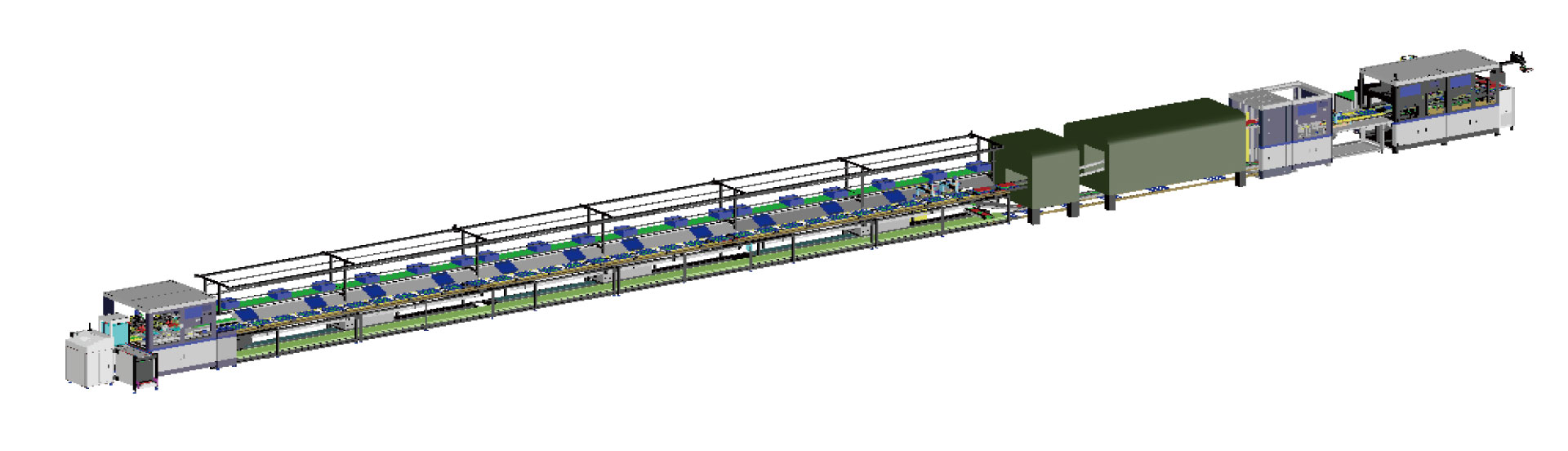

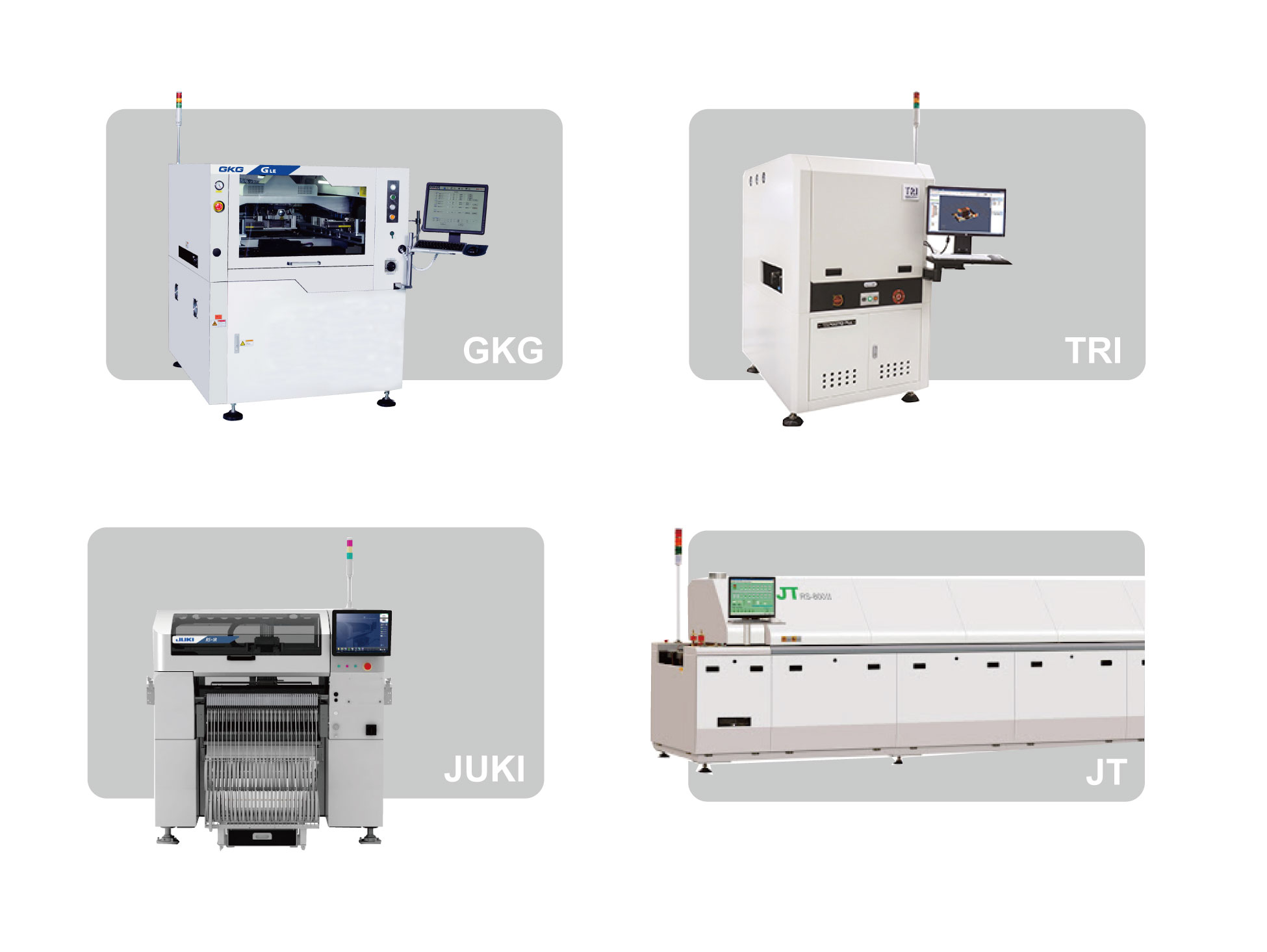

SMT Production Line

The SMT production lines are managed by MES (Manufacturing Executive System), which provides stable and high quality fully automatic SMT OEM production lines (printing, mounting, reflow-soldering, testing). ISO9001 is introduced to provide the best service to our customers.